Built structures

Mass stabilization

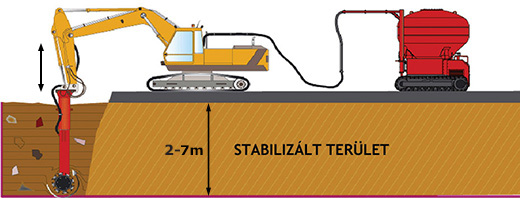

Mass stabilization process

Purpose:

- increase of soil load bearing capacity and strength,

- reduction of settlement,

- improvement of dynamic rigidity of weak soils.

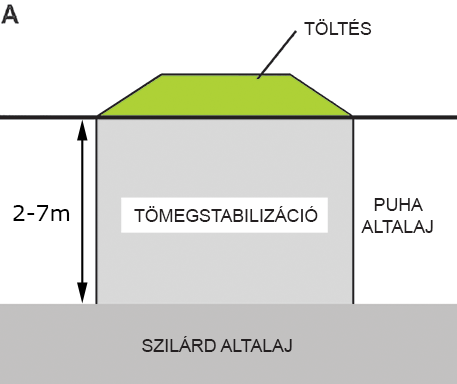

In the mass stabilization process a binder is added to the weak soil to increase its stability. The binder usually is lime, cement or a mixture of the two. By the application of the stabilization process the various weak soil types, e.g. peat, silt or weak soils with high water content can be converted into soils with high load bearing capacity. The mass stabilization process can be used without any additional technology where it is technically suffi cient to treat a maximum 7 m deep layer. In cases where the depth of soil to be treated exceeds this value, mass stabilization can be combined with other deep foundation technologies like gravel pile or concrete pile foundation or deep foundation, etc.

The two types of mass stabilization:

1. Soil is mixed in situ without excavation. In this process a special pneumatic feeder delivers the binder to the special mixer head which homogenizes and additive and the soil.

2. Soil to be treated is excavated and is mixed in a storage area (a ‘tub’) in the way described above then fi lled back into its original location.

Decontamination

Purpose:

- isolation of the contaminated soil,

- neutralization and/or binding of the contaminating waste.

The process can also be used for the in situ treatment of contaminated soils by isolating the contaminating material within the soil and thus preventing its spread into the environment. After neutralizing and stabilizing the contaminated soil can be reused.

Application

- Decontamination of contaminated soil masses, creating areas for further use.

- Recycling of industrial wastes.

- Strengthening, isolation and neutralizing of weak wastes.

Examples of application

Geotechnology

Stabilization of weak, organic, unsuitable soils, peat underlying roads, railroads, industrial facilities, dockyards to make them suitable for construction.

Foundation work for high speed railway

Luhdanoja, Finland

Area of mass stabilized land: 40 m x 300 m = 12 000 m2 (extended at a later date)

Depth: 2-5 m

Binder: cement

The basic purpose is to create, using the mass stabilization technology, a load bearing subsoil that minimizes settlement and provides proper support, with special regard to the dynamic load created by the railroad traffi c.

The treated land was made up two different areas:

Area 1: Weak material down to 5 m depth

Area 2: Clayey soil in agricultural area to 1 m depth and peat down to 5 m depth.

Environment protection

Stabilization and isolation of contaminated soil, neutralizing and binding of contaminating waste.

Trodheim Port, Norway

A project was started to stabilize 15 000 m3 contaminated soil located at the seabed. The project was jointly started by the authorities, consultants and a contractor.

The soil contained PCB, PAH, TBT and heavy metals. After the conclusion of the feasibility study and the initial tests work was organized in the following way:

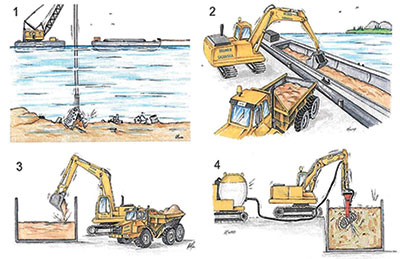

Contaminated soil was excavated by a special fl oating excavator onto a barge, covered and shipped away (fi gure 1). An excavator loaded the soil from the barge on trucks (fi gure 2) to carry it to a 150 m3 mixing tub (fi gure 3) where it was stabilized using a mixture of industrial cement and fl y ash.

Mixing was done by the mass stabilization mixer (fi gure 4). After mixing the material was transported to a landfi ll.

Benefits of mass stabilization

- Quick, cost effi cient, environment-friendly process

- There is no need to transport and to place in landfi ll the excavated material and to import fi ll material which results in considerable reduction of cost and load on the environment

- Use of imported virgin materials can be reduced to a minimum

- The treated material will become suitable for earthwork construction

- Low operating costs

- The strength of treated soils can be controlled by adjusting the binder feed

- The stabilized soil block is much more homogenous than with other processes

- Industrial by-products can be used as raw material

- It is practically insensitive to weather conditions

- It can be used also in water covered areas.

Summary

Mass stabilization can be an economic solution in any situation where soil improvement is required over a large land area.

Application:

- Before the construction of road and railroad embankments to strengthen weak soils in-situ

- Stabilization of weak soils under shopping centers, residential areas,

- Preparation of land for the construction of ports and storage areas, even by mass stabilizing excavated silt

- Stabilization and decontamination of excavated silt,

- Decontamination of contaminated areas,

- Embankment broadening on week subsoils,

- Improving impermeability of dams, by in-mixing of e.g. bentonite,

- Stabilization of organic, peaty or other weak soils under dams and dikes,

- Strengthening of cable/pipeline tracks. Decontamination with the mass stabilization process is an extremely effi cient and economic environment protection solution.